Condmaster Ruby is advanced software for condition monitoring in marine and offshore operations, providing diagnostics, analysis, and decision support for all SPM online systems and portable instruments.

Powerful analysis and decision support

Condmaster Ruby offers a user-friendly interface and strong visualization tools, making it easy to move from fleet or vessel overview to detailed machinery data. The software supports all HD technologies and provides advanced analysis, alert management, and AI-based decision support to streamline monitoring work.

Clear green-yellow-red color coding provides immediate insight into the condition of machinery at every level, from propulsion lines to auxiliary systems.

FLEXIBILITY AND EFFICIENCY

INTEROPERABILITY

INSTANT CONDITION EVALUATION

By clicking “Submit”, you agree that your message and personal details will be sent by email to relevant recipient(s) at SPM Instrument. You hereby also agree that SPM Instrument and its subsidiaries will have access to the information you have provided and that these data will be stored on our email server. The data will not be saved in any other way. We will not use this information to contact you about matters other than those specified in your request. We will not share your information with third parties.

Features

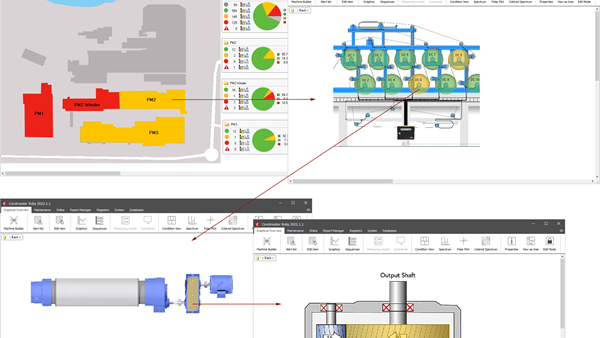

Graphical Overview

The Graphical Overview enables the visualization of plant equipment and mechanical condition in a very intuitive, top-down perspective.

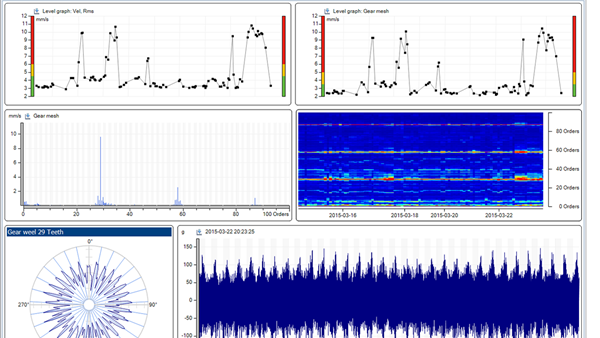

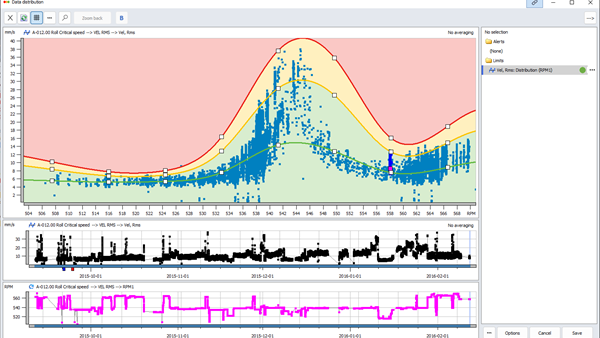

Condition View

Condition View – a powerful tool for presentation and further analysis with multiple graph types and measuring assignments combined in a single window.

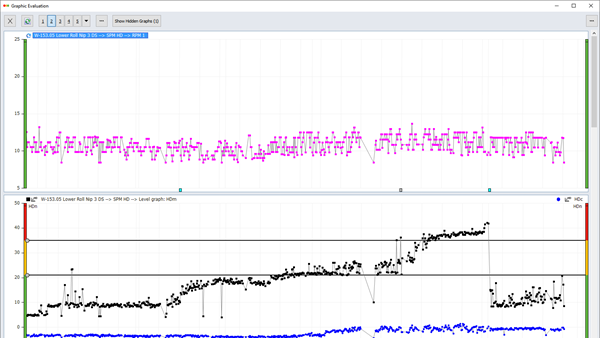

Graphic Evaluation

The Graphic Evaluation function offers an easy-to-understand condition evaluation in green-yellow-red scales on the Y-axis.

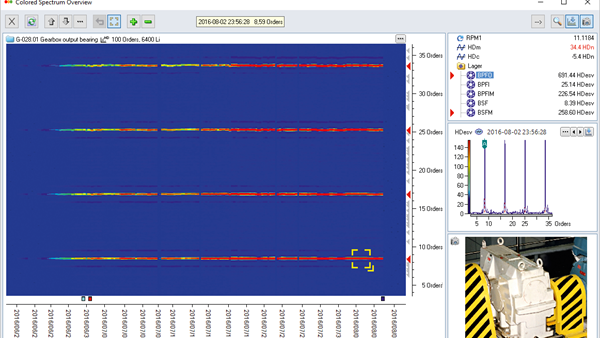

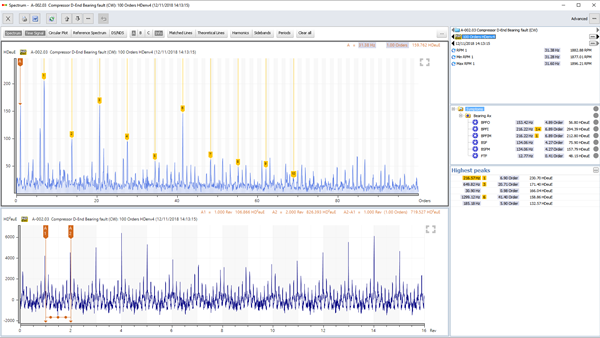

Spectrums and time signals

High-performance vibration analysis with razor-sharp spectrums and time signals bring root cause analysis to a new level of understanding.

... and much, much more. Contact your nearest sales representative today to learn more about all your analysis options with the Condmaster software.

License packaging

Condmaster 2026 is available in editions tailored to operational needs at sea and offshore

The Lite edition provides the essential functions to get started, while Plus, Premium, Superior, and Ultimate add progressively more advanced capabilities for growing monitoring requirements. Product editions are designed to support online systems, giving you full flexibility to choose the workflow that fits your vessel or offshore installation.

For additional customization, optional add-ons can be added to any edition.

Contact your nearest sales representative today to learn more about the Licence packaging.

|

|

|

|

|

|

|

|

|

| Platform |

|

HDm/HDc, Health score, ISO10816, ISO2372, RPM, Temperature, User-defined measurements, Alert management, Colored Spectrum Overview (CSO), Condition View, Data distribution, Entity rules, Machine Builder, Machine baseline, Online, Plant performer, SAP and AMOS links, Signal Quality Test, Voice recording |

| Functions |

|

Level 1 (FFT with symptoms) |

|||||||

|

Level 2 (EVAM incl. Multi-channel measurements, High resolution and frequency, HD ENV) |

|||||||

|

Level 3 (LR/HR HD and Lubmaster, SPM HD Expert) |

|||||||

|

Level 4 (Orbit analysis, Shaft centerline plot, Run up/coast down, Bump test, FRF) |

|||||||

|

SPM Classic (dBm/dBc, LR/HR and Lubmaster and SPM Spectrum) |

Add-on | Add-on | Add-on | Add-on | |||

|

Marine (ISO 20283-5) |

Add-on | Add-on | Add-on | Add-on | |||

|

Rule-Based Evaluation |

Add-on | Add-on | Add-on | Add-on | |||

|

Integration (OPC UA/DA import, CES REST API, OPC UA/DA, Modbus TCP) |

Add-on | Add-on | Add-on | Add-on | Add-on | Add-on |

| Features |

|

Condmaster Entity Server (CES) |

|||||||

|

LinX |

|||||||

|

Condmaster Ruby |

|||||||

|

Decision Support System (DSS) |

|||||||

|

CES Service Connector |

Add-on | Add-on | Add-on | Add-on | Add-on | ||

|

Max. no of enabled databases |

No limit | No limit | No limit | No limit | No limit | 1 | 1 |

*HD ENV is not included