Easy-Laser® XT660 is the second member of our Generation XT alignment systems, built upon our new cross-platform technology.

This means you will be able to display data on a multitude of different handheld devices, including our own XT12. With XT660 you can carry out the following:

- Align the machine

- Check base twist

- Check bearing play

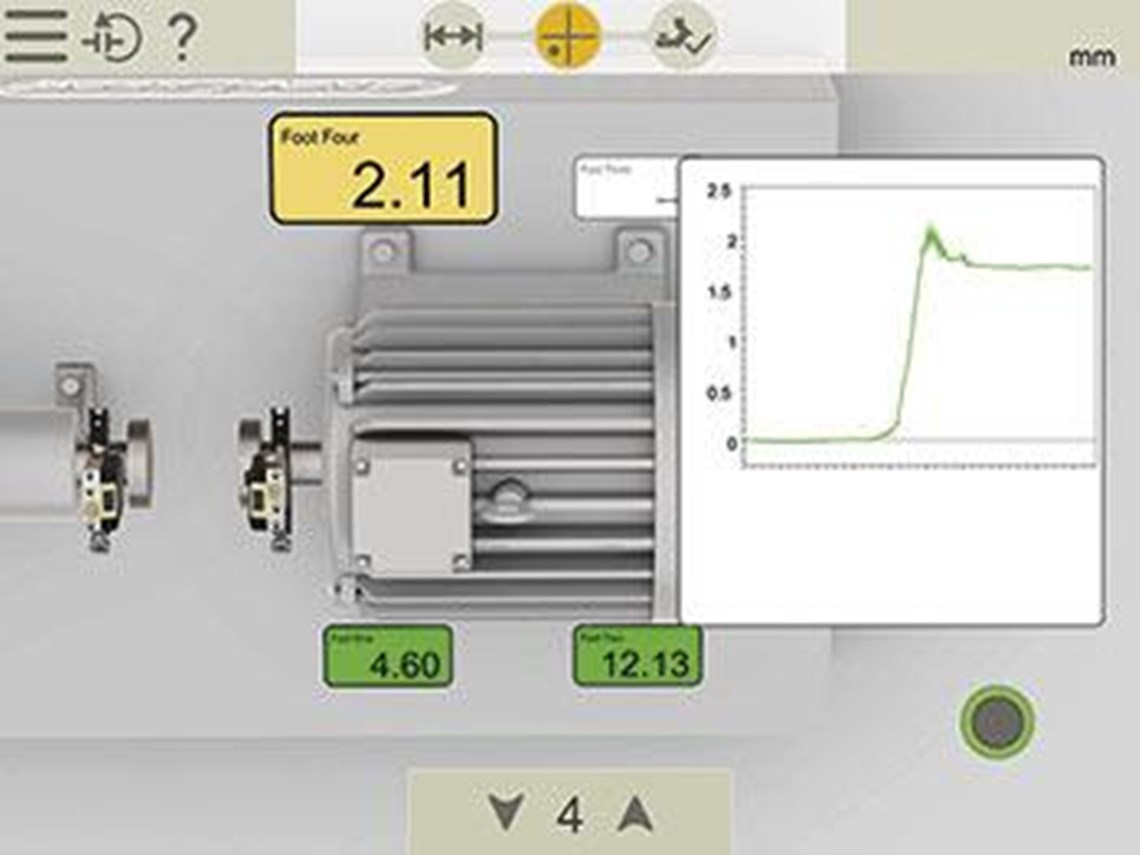

- Check soft foot

- Document and share the result

The XT660 measuring units utilize dot laser technology. This makes it possible to measure larger machines and longer spans than line laser systems. It also provides higher accuracy when backlash in the coupling is present. Also, dot laser allows you to check more things when installing a machine, e.g., twist of foundation and bearing clearance.

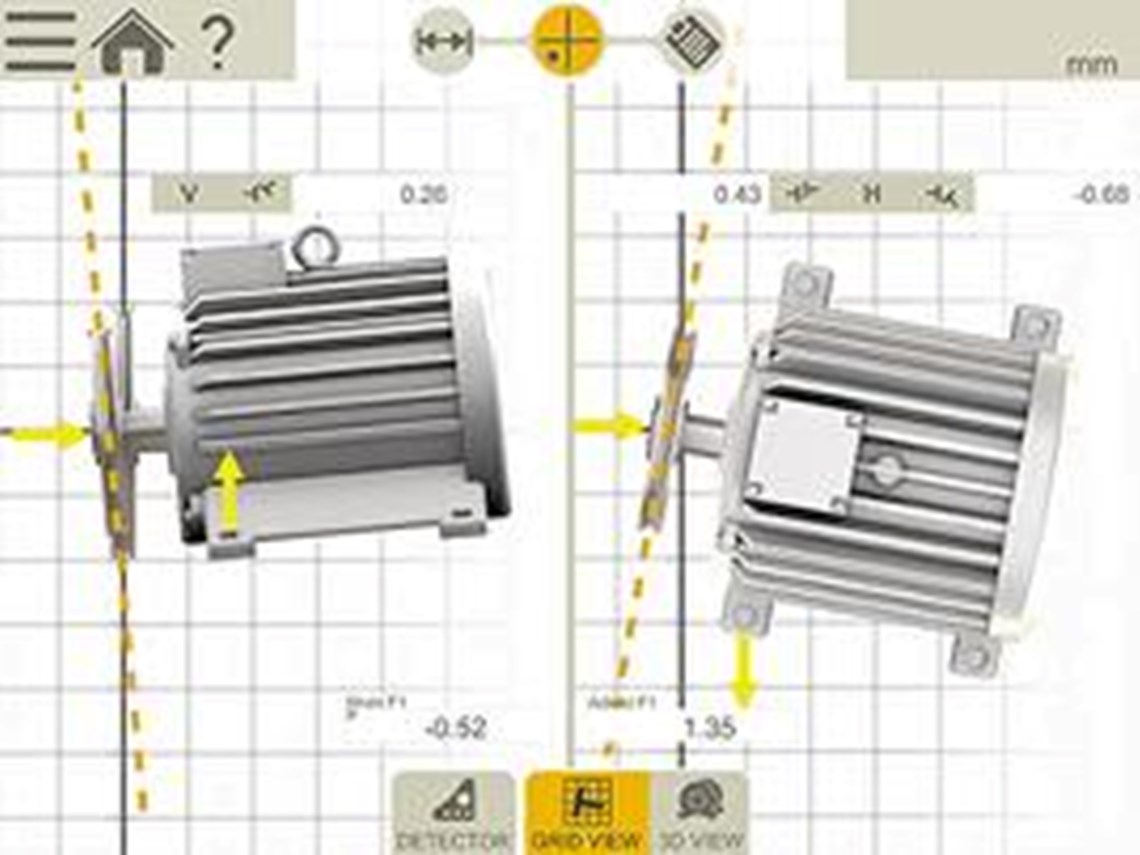

With the XT660, choose between several different measurement methods, e.g., continuous sweep and multipoint. This gives you the flexibility you need to achieve the perfect measurement result.

The XT products are rugged, rated both IP66 and IP67 water and dustproof. Along with long operating times, this guarantees you will be able to take on and finish even the tougher jobs.

User-friendly

Use the rugged Easy-Laser XT12 display unit, or install the free XT Alignment app on your iOS or Android device*. The intuitive user interface guides you through the measurement process.

Unique documentation possibilities

The XT12 display unit has a 13MP camera. You can also get the XT12 display unit with a built-in IR camera**. This means you can add a thermal image of the machine before and after alignment. You can easily create and share a PDF report containing all measurement data and images.

* Click here for a list of compatible devices

** IR Camera is optional

Measuring programs

The featured programs below are the most commonly used with this system. Please click here for a complete overview of possibilities.

*=accessories needed

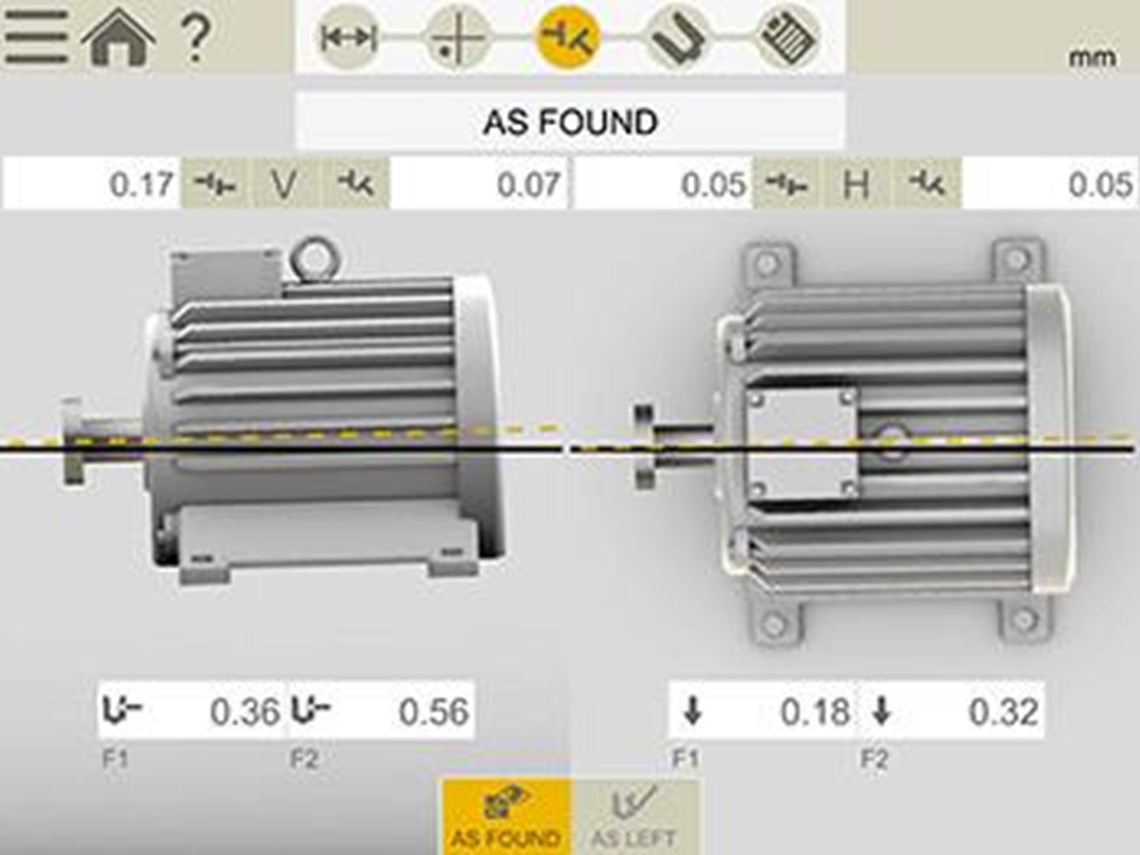

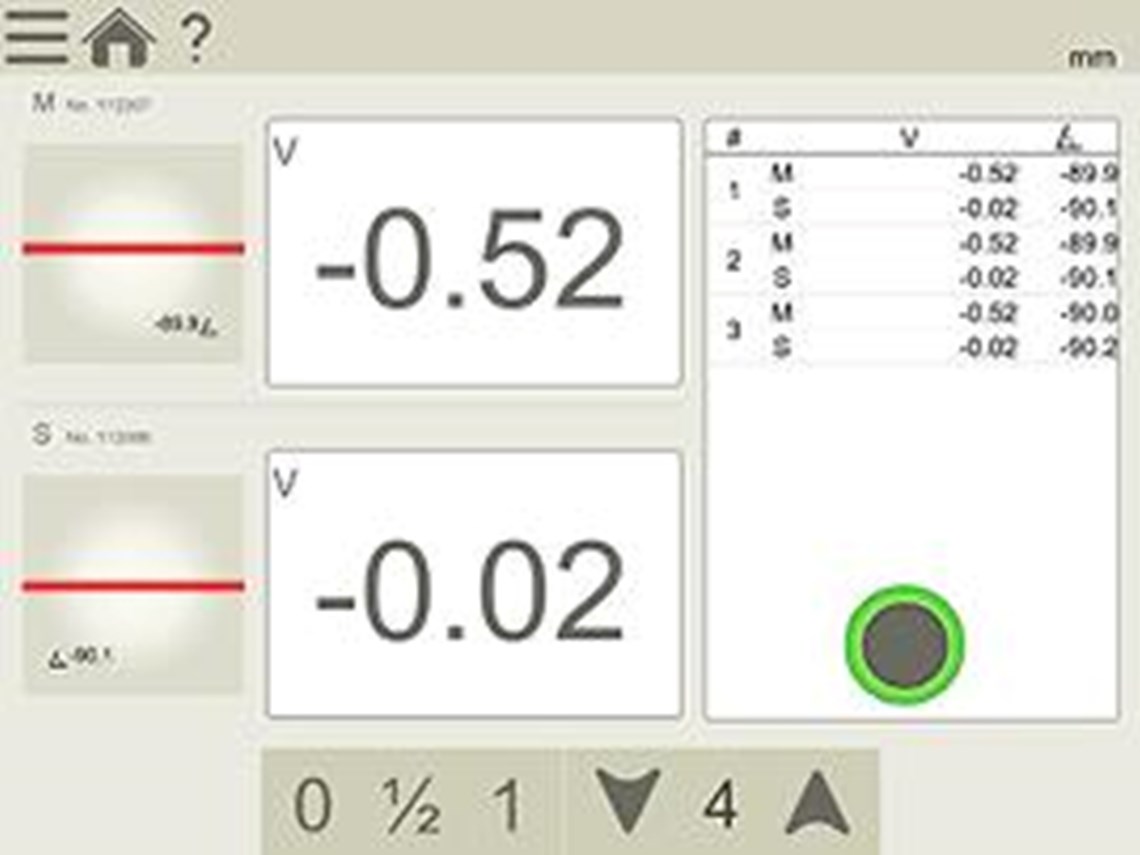

Soft foot check

Alignment work begins with a soft foot check. The soft foot check ensures that the machine is resting evenly on all its feet by indicating which foot/feet should be adjusted. This is an important part of securing a reliable alignment. After the soft foot check is complete, you can go directly to the alignment program with all of the machine’s distance values saved.

Belt alignment*

Using the system, you can align sheaves and pulleys with digital precision. Adjustment of the machines is displayed in real-time on the screen, with readings for angle and axial displacement in both the vertical and horizontal axes, as well as an adjustment value for the front or rear foot pair. The result can be documented as normal. (Requires the XT190 BTA accessory.)

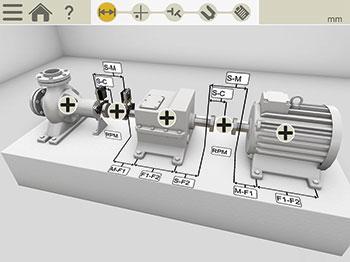

Machine train (3 machines)

For alignment of machine trains with three machines. You can manually pick the reference machine or let the program choose one that will minimize the need for adjustments.

Twist measurement

Program to measure flatness/twist of, for example, machine foundation, machine tables, etc.

Measurement methods

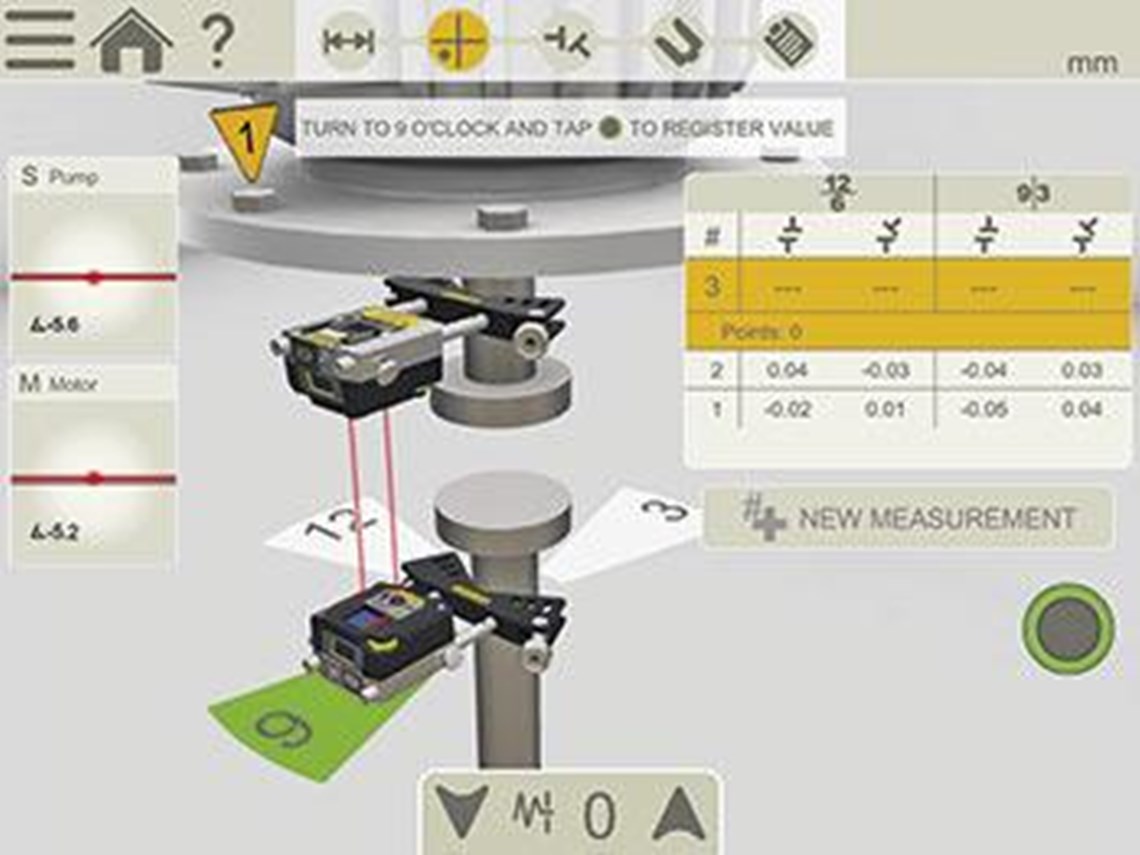

9-12-3

Measurement points are recorded at fixed points 9, 12, and 3 o’clock. This is the classic three-point method that can be used in most cases.

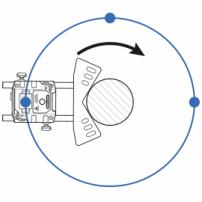

EasyTurn™ function

The EasyTurn™ function allows you to begin the measurement process from anywhere on the turn. You can turn the shaft to any three positions with as little as 20° between each position to register the measurement values. Voila! Measurement is complete!

Multipoint

Multi-point is basically the same as EasyTurn™, but instead, you can record multiple points on the sector rotated. This will provide an optimized calculation basis—perfect for, e.g., turbine and sliding bearing applications.

Continuous sweep

Automatic recording of measurement values during continuous sweeping of the shaft. Hundreds of points are registered. You can start anywhere on the turn. A quality check of measurement is provided.

Technical overview

Display unit

| Name: | XT12 |

| Type of display/size: | VGA 8” color screen, backlit LED, multitouch |

| Internal battery (fixed): | Heavy-duty Li-Ion chargeable |

| Connections: | USB A, USB B, Charger, AV |

| Operating temperature: | −10 to 50 °C |

| Storage temperature: | −20 to 50 °C |

| Communication: | Wireless technology, Wi-Fi |

| Relative humidity: | 10 to 95% |

| OLED display: | 96x96 pixels |

| Camera: | 13 Mp, with diode lamp |

| IR camera (optional): | FLIR LEPTON® (0–450 °C, 32–842 °F) |

| Help functions: | Built-in manual |

| Environmental protection: | IP class 66 and 67 |

| Housing material: | PC/ABS + TPE |

| Dimensions (WxHxD): | 8" LCD capacitive multi-touch colour display |

| Weight: | Heavy-duty Li-Ion chargeable |

| Operating time: | USB A, USB C, Charger, AV |

| −10 to 50 °C | |

| −20 to 50 °C | |

| Wireless technology, Wi-Fi | |

| 10 to 95% | |

| 13 Mp, autofocus, with LED diode lamp | |

| FLIR LEPTON® (0–400 °C, 32–75 °F) | |

| Built-in manual | |

| IP class 66 and 67 | |

| PC-TPE or PC-TPU | |

| 269.0x190.0x49.4 mm [10.59x7.48x1.95"] | |

| 1400 g [49.4 oz] | |

| Up to 16 h continuously |

Measuring units

| Name: | XT60-M/XT60-S |

| Communication: | BT wireless technology |

| Type of detector: | 1 axes TruePSD 20x20 mm [079x0.79”] |

| Resolution: | 0.001 mm [0.05 mils] |

| Measurement accuracy: | ±1µm ±1% |

| Measurement range: | Up to 20 m [33 feet] |

| Type of laser: | Diode laser |

| Laser wavelength: | 635–670 nm |

| Laser class: | Safety class 2 |

| Laser output: | <1 mW |

| Electronic inclinometer: | 0.1° resolution |

| Environmental protection: | IP class 66 and 67 |

| Operating temperature: | −10 to 50 °C |

| Internal battery: | Heavy-duty Li-Ion chargeable |

| Storage temperature: | −20 to 50 °C |

| Relative humidity: | 10 to 95% |

| Housing material: | Anodized aluminum + PC/ABS + TPE |

| Dimensions (WxHxD): | 76x76.7x45.9 mm [3.0x3.0x1.8”] |

| Weight: | 272 g [9.6 oz] |

| OLED display: | 128x64 pixels |

| Operating time: | >24 h continuously |

System parts

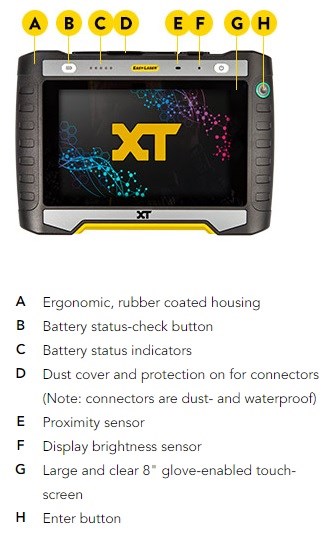

Display unit XT12

Rugged, robust, rubber-coated design. IP66 and 67, dust- water- and shockproof. As standard, a 13 MP camera for documentation is built-in*, and you can also choose to add an IR camera to the XT11.

Glove-enabled touch screen

A large 8", glove-enabled touch-screen makes the information clear and the app easy to use. The small OLED display shows the battery status of both measuring and display units. You can check battery status also when the unit is turned off. The clever lock-screen button prevents unintentional clicks, for instance, when moving between work positions.

*The camera can be removed if security reasons require.

Features

- Robust, rubber-coated design, IP66/67.

- Large 8” glove-enabled touch screen.

- Screen-lock button.

- OLED display shows the battery status.

- IR Camera for thermal images (optional).

- 16 hours of operating time.

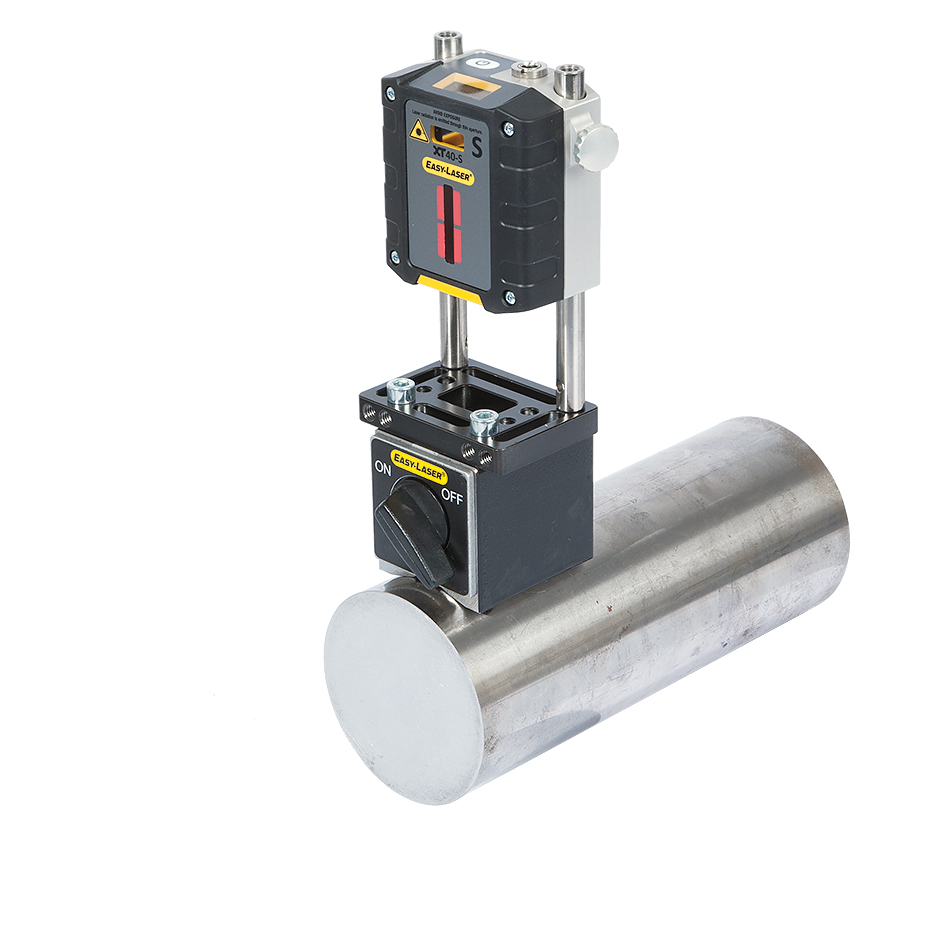

Measuring units XT60-M/XT60-S

The XT60 measuring units utilize dot-type laser and 1-axis square PSD surfaces. A state-of-the-art OLED display shows the unit's angle, making it easier to position it on the shaft.

Rigid and rugged

The diagonally positioned fastening screws set the unit in a grid-lock on the rods. Rigid aluminum housing for maximum stability. IP66 and 67, dust- water- and shockproof. Heavy-duty battery for very long operating times. Built-in wireless technology.

Features

- Built-in wireless technology. Integrated rechargeable battery

- TruePSD technology with an unlimited resolution for the greatest accuracy

- Dual laser beams and PSDs

- Sturdy aluminum body. IP66/67 design

- OLED display shows the angle of the unit

- 24 hours of operating time

A complete system contains

All XT660 shaft systems include:

- 1 measuring unit XT60-M

- 1 measuring unit XT60-S

- 2 shaft brackets with chains and rods

- 4 rods 60 mm [2.36”]

- 2 extension chain 900 mm [35.4"]

- 1 tape measure 3 m [9.8’]

- 1 hexagon wrench set

- 1 charger (100–240 V AC)

- 1 DC split cable for charging

- 1 DC to USB adapter for charging

- 1 Quick reference manual

- 1 cleaning cloth for optics

- 1 USB memory with manuals

- 1 documentation folder

XT660 also includes, depending on the system:

- 1 display unit XT12

- 1 shoulder strap for the display unit

- 1 carrying case Medium

- 1 carrying case Large

Accessories